|

This massive 200,000 lb machine is over 60ft wide and

very tall. It runs on deep foundation 39 ft wide rail road tracks set in thick high strength concrete

footings and uses heavy structural concrete bulkheads to hold the pre-tensioning for up to 24 one foot wide or

six 4 ft wide panels or three 8ft. wide panels with a multitude of exotic pre finishes.

The new machine can build anything from wall and floor panels to beams and columns 4 to 16 inch thick

and any width up to 8 ft for our unique hybrid prefinished light weight stay in place columns that are light weight

for international shipping and can be filled on site with heavy fiber DuckSteel Ultracrete to meet the extreme strength

required for high rise buildings. The up flow pumped ultra high strength SCC structural fiber concrete can then

tie the whole building together with conventional rust proof rebar or post tensioning for the high rise buildings, bridges,

etc. We can ship the pre finished hollow light weight beams and columns and then fill the heavy pumped concrete on site as

the building goes up, with no delay between floors as the columns are structural for several floors as is. This hybrid high

rise system can save millions over conventional on site forming and pouring of conventional concrete that has to wait

for days between pours for the super structure to be built on site for the columns and beams before each floor can

be poured and before any of the really time consuming subtrades can even start to build the high rise buildings. The

same 8 ft machine makes the 16 inch thick hollow core pre stressed water proof parking garage floor and roof

panels or bridge and subdivision roads and bridges, The 8 ft wide by 60 ft long 15" panels are

ideal for long span parking garages that need clear spans of 60 feet and over and can be cast at the rate of 4,800 to

5,000 sq ft per hour, nearly 40,000 sq. ft per 8 hour shift or nearly 120,000 sq. ft per day with stack casting and extra

long casting beds..

Find out how we can save you millions on most any large project.

Scroll down to bottom as you read and then return for side bar for much more pictures and

information.

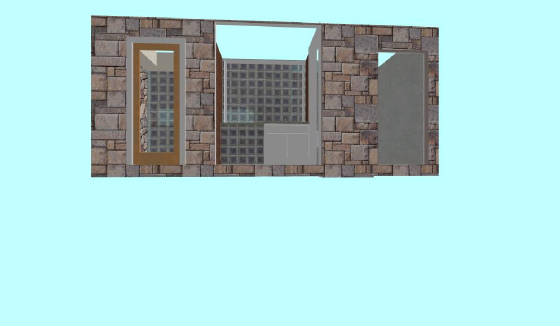

GlobeCast of Ghana is designing and building mid to high rise structures up to 40 + stories with revolutionary light

weight trussed pre-cast pre-finished panel concrete technology that can ship any size building world wide at very affordable

prices. The unique Design-Manufacture-Ship- Build-Finance Company saves months of construction time by pre-building

the flat light weight modular truss panels and complete 3 d kitchens, baths, operating, and nursing rooms

in cores 8 ft by 20 to 40 ft. long by 8 or 10 ft tall modules of light weight pre-cast pre-finished pre- plumbed systems

built in the factory 24 7 365 so the building can be built to 95 % completion on the ground in ultra modern high quality designer pre-finished

and pre-glassed light weight panels built in the factory while the site is being prepared. The complete structure

can be erected at 10 to 40,000 sq ft per day ( about 10,000 sq ft per crane)

We also have special funding for large pre-designed 2 to 5 star hotel/condo/office projects with

creative financing for the

current times. (plenty of funds for right projects anywhere) with money sources from UEA, Europe, Italy, China, Africa

etc. Many developing countries have such extreme shortage of houses that they were not that effected by the mortgage problems.

There is plenty of money available for the right projects that have good financial market flow and good land equity

and

sufficient capital to weather any slow downs. We will work

with REITS, Pension Funds and private investors, land owners, contractors, architects, engineers, builders, developers

by contract or joint venture projects to any stage of completion.

We can often save million of dollars and shave months or even years off the move in time of many construction projects.

You can not afford to build any other way.

The time savings alone is amazing.

Globe Cast LLC. is building one of the world largest automated pre-cast plants designed and built by TSV FabCo.

for international shipping of module sized light weight pre cast truss Syn-Steel Hollowcore and foam core architectural walls

of UHS DuckSteel Ultracrete concrete, Pre finished and Pre wired and Plumbed architectual panels, as well as light weight

hollow core fiber reinforced ultra high strength pre-stress panels for clear spans that use multi pre-stressed 1/2 inch steelcables

for the long 30 to 66 ft.clear spans needed for the floors and roofs for modular malls, condos, apartments, hotels, offices,

parking garages, drive ways, streets and roads, etc. The revolutionary systems uses new DuckSteel UltraCrete technology in

new ultra light hollow core prestress for the long 30 to 66 ft spans and uses ultra syn steel fibers in proprietary "3D continual

reinforced ultra high strength fiber concrete with concrete and foam web members for a true structural Trusspanels, made

with proprietary structural "Ultra High Strength" 6,000 to 30,000 psi ductal "Duck-Steel" concrete with with their proprietary

high density blend of long and short steel like "Syn-Steel" fibers, using up to 50 lbs of fibers per cu. yard. Each phase

is covered by a team of proven system subcontrctors from design, site preparation, factory production and shipping along with

expert crane erection.

| 8 ft. by 20 ft. pre built 2 baths and Kitchen |

|

| ready to use with airconditioning and sprinkler system |

|

|

This model has the main 2 ft deep by 20 ft open kitchen wall on one side with a 4 ft by 8 ft designer concrete or granite

Island counter shipped verticle in side one of the bath rooms or in the one bath one closet model it is shipped

in the closet or hallway area, and in the second bath in the 2 bath module. The

ready to use baths have state of the art rain showers with massage and heat. they also have optional Spa infinity

edge water fall tubs,with exotic sinks and cabinets and optional see thru large glass electic fireplaces options that

would cost thousands more if indiviually built by conventional designer. Optional inset for up to 60 inch big screen tv cast

above fireplace with cables per installed.

Most all plans have 10 to 20 ft high ceilings and many

plans have 20 to 30 ft open spans with open island kitchens overlooking

large 10 ft by 20 to 30 ft. Solar Glass walls overlooking exciting 8 ft by 20ft.

designer stone decks with see thru thin cable railings.

Make sure you see the gallery page of this site for a sample of the many unique colors,

styles and finishes for kitchens and baths available for hotels,

and condo apartments.

The Ghana Plant in the Port of Tema will be one of the largest and only with revolutionary DuckSteel UltraCrete high

fiber precast plant in the world. It will be the first with the ultra light all inclusive fiber cast "architectural trussed

panels", offering optional 4 layers of tempered safety Therma Glaze reflective active solar walls, along with revolutionary

ready to use designer baths, kitchens, complete with air conditioning, electrical, and plumbing. The light weight concrete

foam core modules will be built in 8 ft wide and up to 40 ft long. They will be built with propietary molding machinery that

is precision computer controlled batching with onsite

concrete testing and formulation concrete ad mixture and particle sizing technology for the best quality and highest design

stregth needed for each product cast with

the TSV automated molding and batching machinery and will use the patent pending "3D Truss"DuckSteel"Ultracrete" Panel system

that use Ultra High Stength Structural steel like "Synsteel fibers" and proprietary patented additives to achieve concrete

strengths up to the 30 or 40 psi range which is strong as steel.

scroll back to top and use side bar for more info.

|

|

|

Contact the USA communication center in English only for GC Tec, GlobeCast of Ghana and "TSV FabCo" the equipment manufacturer

of Dubia 936 333 5695

GC Tec

|

|

|

|

GlobeCast PreCast-factory will build regular 4 ft and 8 ft. wide hollow core in in thickness of 4 inch to 16 inch

and any length cast in automated lines 600 ft. long.

The flat lighter weight panels can be cut to any length in thickness from 4 inch to 16 inch in pre stressed

hollowcore as well as the new light weight fiber reinforced

hollow core that is revolutionary for parking garages and commercial building that need clear spans of up to 66 ft. and

can build truss systems of clear spans under the trusses for nearly any normal width and any length and heights of over

40 + stories with special post tensioning in their new Hybrid cast in place pre finished concrete or steel pre

finished column and beam systems.

|

|

|

|

|

|